How to Soft-Wash in Canada

Using a Soft-Wash System or Pressure Washer to Soft-Wash in Canada

When it comes to soft washing there are several ways this can be done. In this post we will break down some common ways to achieve a true soft wash using a Soft-Wash System or a Pressure Washer. While using a dedicated “Soft-Wash System” you will typically achieve a high volume of fluid but a lower overall pressure. While using a “Pressure Washer” you will achieve a lower volume but a much higher pressure. Now, the trick to get your pressure lowered while using a pressure washer is to simply adjust the size of your tips at the end of the gun. For example, let’s say you have a 4GPM pressure washer that is rated for 4000PSI. If you were using a tip that is rated for use with a 4GPM unit then you would be most likely achieving around 3500-PSI. However, if you were to use a tip rated for use with a 8GPM unit then you would be cutting your PSI in half because the orifice size is 2Xs as big on the 8GPM. Now, even though you put on a larger orifice tip, your pressure washer is still set up for use at 4GPM. Since the orifice is twice as big it causes the pressure to drop by 50% to around 1750PSI. Adjusting to an "oversized tip" is a great way to lower your PSI output. This is why many of the professional soft washing companies in Canada will use a 40GPM tip with a 4GPM pressure washer to reduce our PSI into the 100s instead of in the 1000s.

Let’s break down a few methods you can use to soft wash using a pressure washer. We will talk about 3 ways to do this:

X-Jetting - This is great way to get started with soft washing. With this type of soft washing you will be be able to get a stronger mix then down streaming as the chemical injection happens right near the gun tip via a hose that you insert into a bucket. It typically gives you 3 parts water to 1 part detergent mix ( If you are using a bucket of 12.5% SH then you can expect a 3-4% SH mix to be coming out the gun.

With X-Jetting you will need to carry the bucket, filled with your desired mix around with you and insert the hose into the bucket then spray the solution onto the surface that you are cleaning. You can modify the length of your hose to maximize how far you can move away from the bucket. We recommend using 3/8” rubber airline hose. Just be sure to have a filter on the end of the hose that will get inserted into the bucket and closed to the gun you will want to install a 1/4” PVC Ball Valve (Item#3026). This ball valve will help stop your mix from siphoning out of the hose when you are not using it. Check out our video explaining this on our Youtube channel.

https://www.youtube.com/watch?v=kHpvy0-B7qs&t=42s

Other ideas for X-Jetting that have been used in the past is to mount a bucket onto a cart dolly, then strap it to the dolly so you will be able to move the dolly around a building or house and use your X-Jet. This works good when starting out with larger commercial buildings with lots of space to move around.

When working in an Ariel lift you can also bring a bucket into the lift with you and use the X-Jet directly from there. This is a great way to get a strong mix of detergent onto a large area very quickly!

Down Streaming - With this type of soft washing the injection happens right after the pump, hence the name “Downstream” (downstream of the pump). With this, you can leave your bucket of detergent near your pressure washer and avoid carrying around a heavy bucket. Downstreaming typically produces a 10 parts water to 1 part detergent mix (10:1). When you are using 12.5% SH this will create the perfect mix for many exterior surfaces like vinyl siding, hardy board, windows etc.

Down streaming is great because you can utilize the power of your pressure washer pump to shoot your mix at hard to reach areas. With down streaming you will need to use the proper nozzles to help the injection process happen. Here is a quick breakdown of how to use your nozzles properly.

When you pull the trigger while using your soap nozzles (bigger orifice) this will cause a Venturi (vacuum effect) at the injection point and cause the injector to suck up the detergent from the bucket and then force it down the high pressure hose and out the end of your gun. If you use the rinse nozzles (smaller orifice) on your JROD then the ball inside of the injector will not shift and no detergent will be injected (sucked) into the line. So you can use your soap nozzles while working on applying your detergent to the building then switch to the rinsing nozzles and no more soap will come out.

Another way to rinse while still using your soap nozzles is to instal an “Injector bypass” which will allow the water to bypass the injector and optimize the water flow. After you have soaped as much surface that you are working on you can walk back to your pressure washer, open the ball valve on the injector bypass and continue to use your high flow soap nozzles for rinsing with just water.

For mixing ratios when X-Jetting keep in mind that you are technically “batch mixing” Which means you are adding all of your detergents and soaps into one bucket then drawing directly from it. So, in a 20 litre or 5 gallon bucket we like to use a mix of:

- 4oz Dragon Grip (Surfactant)

- 4oz EBC Glide (Window Rinsing Aid)

- 2oz Apple Boost (Scent Cover)

- 2oz EBC Multi Purpose De-Greaser (Soot,Spiders & Carbon)

This mix is amazing but if you are wanting to keep cost down then simply using Dragon Grip is 100% fine.

Down Stream Injecting allows you to:

Spray different detergents easily at different ratios. You can spray just about anything through your injector including SH, Acids, DeGreasers or pretty much anything that you want to.

Down Stream Injecting typically gives a weaker mix than using an X-Jet or a SoftWash System, so you are limited to the things that you can clean while downstreaming. For example, surfaces such as roofs, stucco or heavily oil stained areas often need stronger ratios than what a downstream injector can produce. Keep in mind that there are always exceptions to the rule as there are some new injectors on the market that do promise higher draw rates.

Dual Barb Injection with Soap Metering Valve - This is pretty much the same as regular Down Stream Injecting with the difference being that this setup has 2 injection points on the same injector. One of the great advantages of this is that you can utilize the power of Apple Wash surfactant to its full potential by having one hose directly into the SH and the second hose (With the soap metering valve) directly into a bucket with your concentrated soap mix. Look at this photo below and also use this link to see our You Tube video.

https://www.youtube.com/watch?v=HBIALh2a1Dc&t=42s

In that soap mix we like to use a 20 litre bucket (5 Gallons) and we add:

- 1.5 gallons of Applewash (Helps bleach dwell longer, Smells Great, Acts as a marker soap)

- 10 oz EBC Glide (Helps windows Clean up better)

- 6 oz EBC Multi purpose degreaser (Helps with general stains, carbon, spider webs etc)

- 8 oz of Apple Boost (will cover the smell of the SH)

This mix is amazing but if you are wanting to keep cost down then simply using Applewash is 100% fine.

Typically, your skid will come with some type of pump, water tank, SH tank, soap tanks, hose reels, hoses and a softwash gun with the proper nozzles. Usually, there will be some nozzles for applying detergent to low areas and some zero degree nozzles to hit the high up areas. Your skid may also include a Proportioner system which will allow you to draw specific amounts of product from each individual tank so that you can get the perfect mix ratio for the surface that you are cleaning. This ability to adjust your mix on the fly will bring great benefits by allowing you to use the least amount of detergent needed for a certain application. Other benefits would be:

Not using too strong of a mix on the area you are cleaning by knowing 100% what your current mix levels are. Keep in mind, you will still want to be fully trained or experienced to ensure you do not apply too “hot” of a mix on the surface you are cleaning. Be sure to attend one of Big Shot Supplies group training sessions or even one of our private 1 on 1 training classes to get fully competent on mix ratios for every surface plus so much more.

Also, by having separate tanks for each fluid you will keep your water clean & your SH pure and free from being contaminated. You will have 1 tank full of soap specific for building /house washing and 1 tank specific for roof washing. You will be able to switch between soaps using a 3 way ball valve.

Here is a short list of benefits you will gain from using a Pro Portioner System.

- Much faster time to train employees to use the PP rather that teaching them how to keep track of batch mix levels and transferring SH into your mix every time you need a differ ratio!

- Change your mix on the fly so if your roof washing job randomly ask you to clean their house you can simply adjust your SH strength and change your type of soap.

- Reduce the risk of using "too hot of a mix" for the surface you are cleaning

- Plus, so much more.

Now lets take a few minutes to break down the 3 types of Soft Washing Skids that you will most likely be interested in.

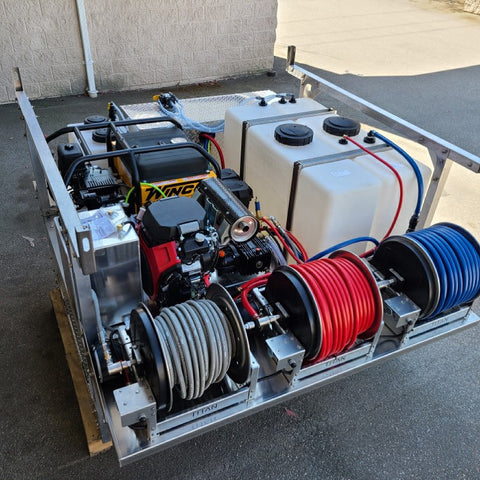

First, is a pre built Soft Wash System or sometimes called a "Pallet Sized Skid". They come in all shapes and sizes and can be built very compact on a skid the size of a pallet that can be lifted into your truck, trailer or van. See pic below.

A pallet sized skid as pictured above will usually be around the size of a pallet and be short enough to fit into most work vans and truthfully the possibilities are endless to where you place your skid. You can instal it through the side door of a van, back of a pickup box, on a flatbed truck or even inside of a cube van. It will have everything you need to soft wash and everything will be plumbed up ahead of time and ready to go. You will most likely need to properly prime the system on its first use to bleed out any air in the system and the lines. These systems can run you anywhere from $6,000-$15,000 on average depending on the type of pump you use and the accessories you choose to add.

Skids can also be built to fit perfectly in the back of a long box or short box truck. We would call this a “Drop In Skid” as you can see in the pictures below.

A "Drop In Skid" is similar to a pallet skid however, it will sit perfectly into the entire box of your truck which will maximize all of the space. Often these systems will have a soft wash setup along with a pressure washing system plus a ladder rack. This is the best way to maximize the space available in the box of your truck and it’s usually recommended to have a 1 tonne truck which will also allow you still pull a cargo trailer if needed.

These systems can run you anywhere from $30,000-$100,000 depending on the equipment you desire.

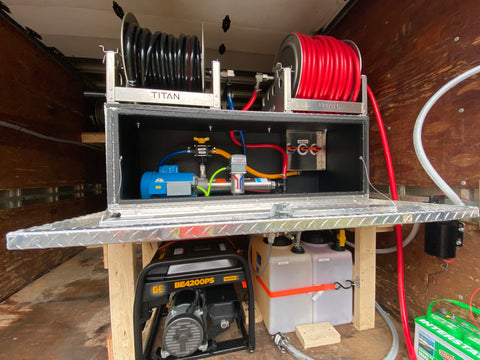

You can also build your own or have someone build a custom setup so you can put each item neatly inside your work vehicle exactly where you want in order to efficiently maximize your available space. See pics below.

Doing this work yourself will allow you to fully understand exactly how everything works and also allow you to understand the maintenance much better. Often this is an ongoing project that gets modified over time as you become more knowledgeable and try out new configurations. Having a basic understanding of plumbing and building is definitely an asset but we will admit that it can be very stressful figuring out how everything should be set up and how to maximize space. If this seems like something you will struggle with it may be a good idea to consider buying something that is pre built or have someone build your custom setup for you.

You can buy almost any type of skid to suit your needs and hopefully this post has helped you decide what will work best for you and your company as it continues to grow.

Check out our main washing website where we often post new pictures and videos that how us using our various softwash systems. Follow this link.

www.bigshotpressurewashing.com

Hi, i’m have a really big interest of starting a soft washing business at part time. First question, is it possible to have it installed in Dodge Caravan?

I leave in quebec Gatineau and french is my first language. Do you course un french?